One Tractor. Many Uses.

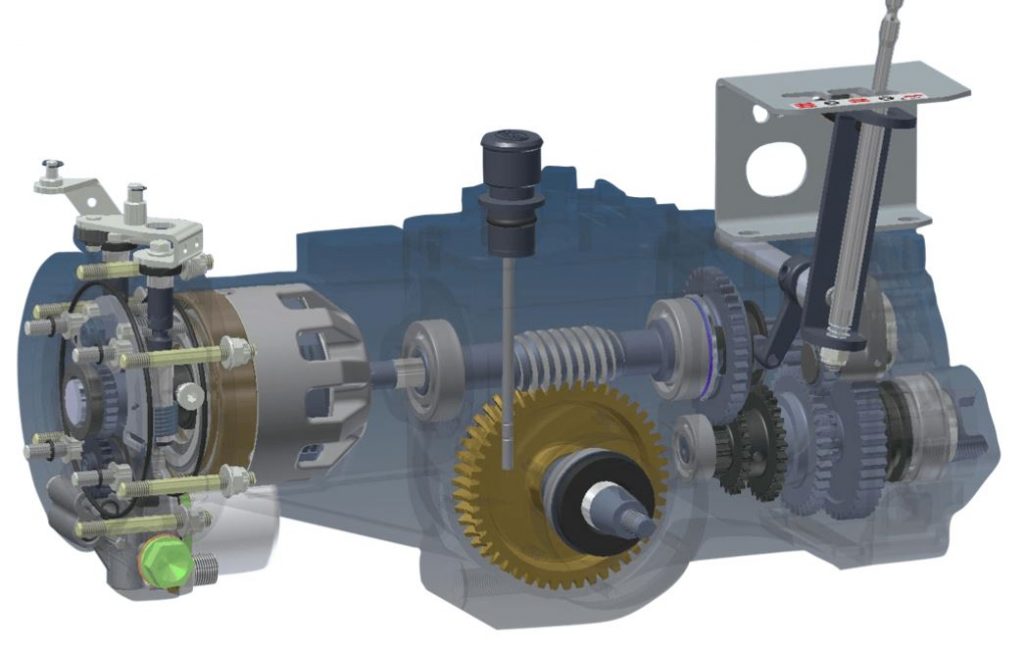

Built to the same commercial standards as four-wheel farm tractors, BCS tackles the jobs that don’t suit four-wheel tractors: mowing slopes, maneuvering in small areas, intensive cultivation, sweeping walkways, and much more! Check out the video below or scroll down for more information about BCS 2-wheeled tractors.

The video below demonstrates the model 710 tractor being used with several BCS attachments including the rear tine tiller, sickle mower, & the 40″ broom.

The BCS Fall Sale is currently in progress! Save up to 10% off a large variety of tractors and attachments. We also have additional deep discounts available on select units in stock. Now is a great time to buy a BCS. Click the button below for sale pricing.

Wenger Equipment LLC is your local BCS dealer for Central WI. We offer rentals and demonstrations for several BCS tractors and attachments so you can experience the performance and versatility of BCS tractors and attachments yourself. We also offer free delivery and personal operation instructions to all of our customers located in Central WI with any tractor purchase.

Request a brochure or visit www.bcsamerica.com for a complete listing of tractors, attachments and specifications.

BCS: PERFORMANCE. DURABILITY. VERSATILITY.

Fill out this form to receive a free copy of the current BCS catalog and Fall Sale price list. If you fill in the address field we will send you a paper catalog and price list in addition to the copies you receive by email.

Wenger Equipment LLC is your local BCS dealer for the Central WI area including the cities of Wausau, Merrill, Stevens Point, Marshfield, Stratford, Medford and more. We offer rentals and demonstrations for several BCS tractors and attachments so you can experience the performance and versatility of BCS tractors and attachments yourself.

At Wenger Equipment we are committed to treating our customers the way we would want to be treated. We carry high quality equipment from reputable manufacturers in order to give you a great value for your investment. Our goal is to help you select the equipment that will best fit your needs and keep that equipment running for years of dependable service. We have over 34 years of experience serving thousands of satisfied customers in the Central WI area. As an added benefit, when you purchase a new piece of equipment from us you’ll also get a $10 per hour discount off of our posted shop labor rate for all service and repairs for the life of the machine. Its just one way we say “thank you” to our valued customers.